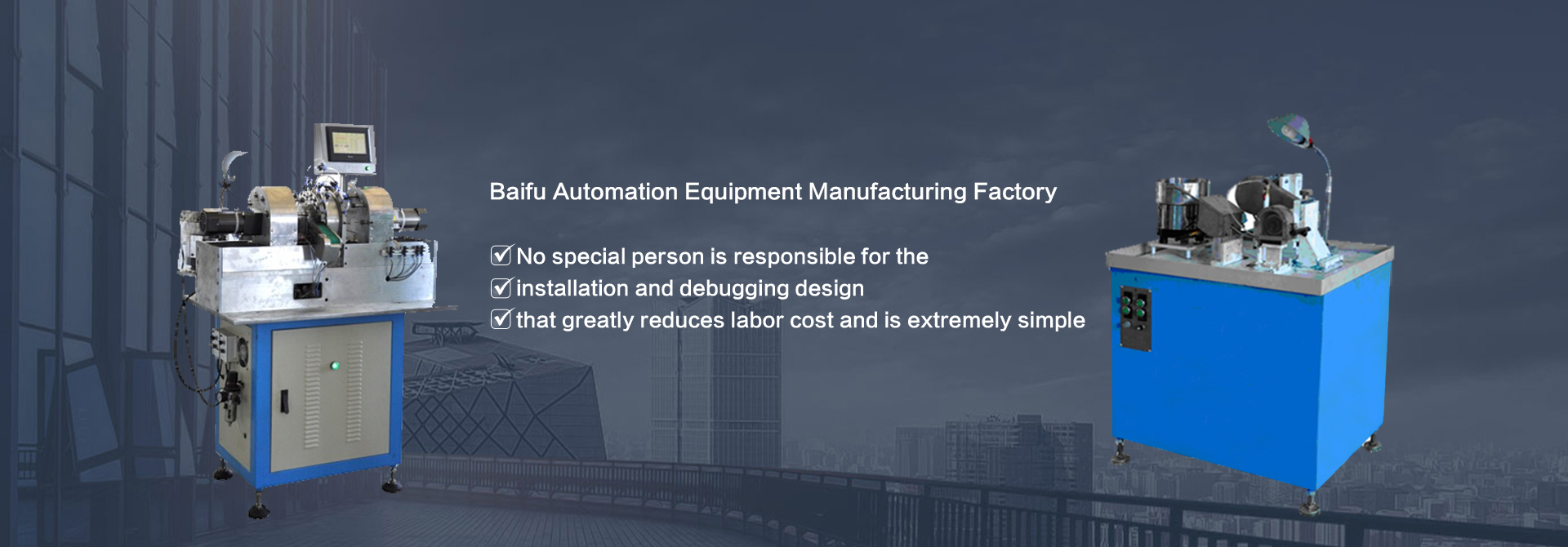

Bidirectional eight chuck zirconia ceramic grinding machine

Dual-head zirconia ceramic optical fiber grinder is the first fully NC automatic finishing equipment in China to ban manual grinding of zirconia ceramic optical fiber sleeve. Since it was put into the market, it has won the recognition of customers for its advantages of high efficiency, high precision and low scrap rate.

The bi-directional eight-clamp zirconia ceramic grinder is the third fully NC automatic equipment for finishing zirconia ceramic optical fiber sleeve introduced by our company after the single-head and double-head zirconia ceramic grinder. It mainly solves the problems of excessive blank allowance and difficult processing in the market. Like the single-head zirconia ceramic grinder, it is the same as the single-head zirconia ceramic grinder. Compared with manual grinding, the inner hole surface after grinding by this equipment has higher smoothness, mirror shape, very smooth, less friction coefficient, good concentricity and inner hole roundness. Compared with single-head zirconia ceramic grinder, the equipment mainly solves the problem of excessive taper (commonly known as bell mouth) in finished products, which improves the precision of grinded zirconia ceramic optical fiber sleeve by one level or even higher, but the efficiency is lower than that of single-head ceramic grinder.

The ceramic grinding machine has the following characteristics:

1, ceramic grinding machine for high-speed grinding machine, precision grinding machine. The belt is made of sand cloth, and the electrical appliances are sprayed by Japan and Quan, Fuji and the whole machine. The color is computer color.

2. The guide rail is Taiwan linear guide.

3. Scraping glue adopts the design of the card lock, which can make the deformation and scraping glue adjust and ensure the grinding quality.

4. This automatic grinder, high-speed grinder and precision grinder can be used for grinding mechanical and manual scrapers.

5. Special grinding wheel design, no pressure sense, no distortion of scraping rubber, no ripple phenomenon, to ensure grinding accuracy.

6, grinding angle to match various special printing efficiency.

7. Ceramic grinder equipped with dust-cleaning device can reduce industrial pollution, and is conducive to staff health and equipment maintenance.

8, ceramic grinding machine, high-speed grinding machine, precision grinding machine is easy to operate, no professional technology can be operated.

The ceramic grinder achieves the grinding effect by extruding the surface of three horizontal rollers and friction at different speeds; adjusting the clearance between the rollers by adjusting the horizontal handwheel screw to adjust the size of the grinded material, which is simple, accurate and easy to operate; the ceramic grinder is equipped with a cooling device, which can dissipate the work of the rollers. The heat generated is guaranteed to work continuously; it is suitable for many varieties and easy to change colors.